Swirls & Streaks

Reprinted from "Crown Jewels of the Wire", August 2004, page 24

Every since Crown Jewels introduced the monthly feature "Insulator of

the Month", collectors have time and again told us their favorite

insulators are those with special character. Quite frequently, that character

involves swirls and streaks of color in the glass.

This month, we present a number of "swirly" insulators in a variety

of CD styles. And we are presenting them "life size". Now, some of

these photographs were taken more than a year ago. So while we don't have the

actual insulators in hand, we present them in a size appropriate to their CD

style. A problem with showing insulators "full size" is that we can't

present as many. But on the positive side, you get to see them as close to how

they appear as possible.

Nearly all older insulators, and some newer ones, can be found with swirls.

On this page, what would ordinarily have been a common, aqua, CD102 pony truly

became a Crown Jewel when impurities in the glass batch caused the beautiful

swirling you see here.

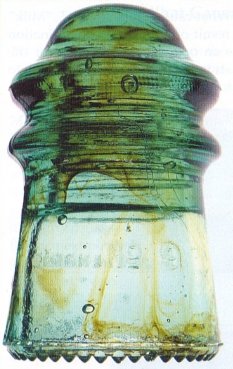

Something old, Something New. That amber swirls can be found in a wide range

of insulators is evidenced by the two shown on this page. The CD 700.1

threadless "egg" telegraph insulator shown above dates from the

1850's. Here the amber swirling is so extensive that the entire insulator color

has been changed from aqua to green tones. Swirling in small amounts can be

found in a great many insulators. But when the swirling dominates the glass, the

insulator becomes a Crown Jewel.

The CD 113 Hemingray # 12 shown below is one-hundred years newer than

the "egg". In this case, a broad band of amber appears orange when

encased in clear glass.

Why so popular? Swirling can turn the ordinary into something extraordinary.

What a surprise it can be to find colorful swirls of glass dancing around inside

an insulator. And ordinary style insulators, even with swirls, are often not

expensive.

Not every collector can afford to purchase a popular style like a CD 159

Gregory, or a CD 119 Brookfield. Some styles, like the CD 111 are unique and not

available to any collector.

But everyone can obtain an insulator that because of its swirls is unique in

and of itself.

(page 25)

What Causes Swirling?

For the answer to what causes those fun swirls everyone seems to love so

much, we present a excepts from an article written by Mark Lauckner and

published in the July 2000 issue of Crown Jewels.

Mark writes, "What causes amber streaks? Amber streaks are caused by

iron oxide (rust) or ferrous containing metals in. the glass. Just one little

fleck or rust or scrap iron causes a nice amber streak when poured. If rusty

steel or iron ladles were used to pour insulators, rust flecks would be left in

the glass tank after each time the ladle was dipped in. These flecks would melt

and make little regions of dark green glass waiting for the ladle to come back

and scoop them up for the next pour. Iron oxide is one of the chemicals used for

coloring glass green. When we refer to amber streaking in glass, it's usually

green that we see."

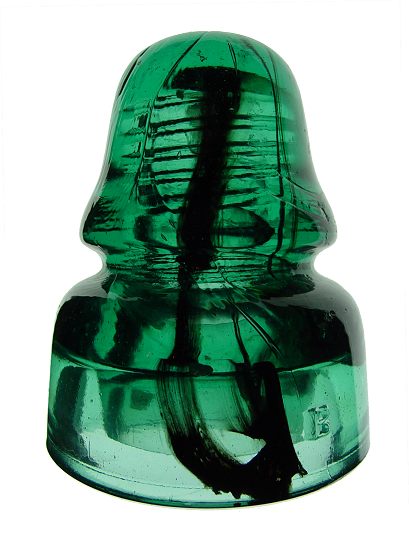

In some insulators, as in this CD 162.5, the amber swirling is so dramatic

that it dominates the insulator even in a black & white photograph. This

particular insulator has been featured in Crown Jewels on several occasions.

(page 26)

Lauckner continues in his article, "What causes milk streaks?

"Milk" or non-transparent streaks are the result of accidental

contamination by a chemical oxide which acts as an opacifier in the glass, or

the deliberate addition of these chemicals in the previous furnace batch to

produce opalescent or opaque glass.

Small milk streaks in insulator would certainly suggest undesired

contamination in the glass tank, while the full swirled milky insulators (like

the Hemingray 12 above) would suggest that transparent glass was loaded on top

of a previous run of opaque or "milk glass", and that some mixing

action in the glass tank had partially blended the two together."

Lauckner's article is called, "The Birth of an Insulator". It's 11

pages in length and features 17 color photographs. The article explains how

"leaners" are formed, what causes underpours, what creates

"snow" in insulator glass, how foreign objects such as nails get

inside insulators, what causes creases and lines on insulators, what causes two

tone insulators, black bubbles and much more. The article is available in

booklet form from Crown Jewels for the price of just $1.00 each to cover postage

and handling. Or, 20 copies can be ordered for $10 post paid (for distribution

at shows or club meetings.)

(page 27)

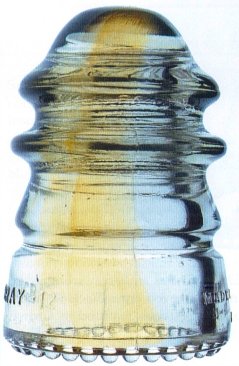

The Hemingray #9, a CD 106, is one of the most common insulators ever

manufactured.

But Hemingray #9's can often be found with heavy amber swirling.

Here a common insulator becomes a unique piece of glass that can still be

acquired at a modest price, or perhaps found undiscovered in a junk box because

the swirls are hidden under soot and dirt.

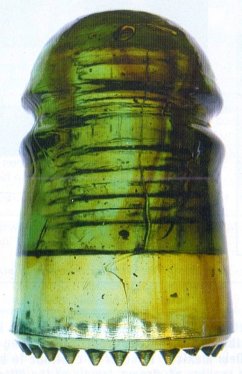

An earlier style of insulator is the Hemingray CD 124.

These are normally found in a plain aqua color.

Examples in bright colors, even when the colors are caused by amber swirls,

are much more difficult to come by.

In this example, it doesn't appear that the Hemingray company had quite

perfected the concept of drip points at the time they made this insulator.

(page 28)

CD 125' s are a large, heavy, bulky insulator. Most frequently a Hemingray

product, the style was possibly introduced to compete with Brookfield's CD 126

"blobtop" design for telegraph insulators.

Early 125's are often embossed W.U. for the Western Union Telegraph Company.

The style is popular to collect because examples are occasionally found in

bright colors including purple, dark sapphire blue, yellow green, and yellow

olive green. (See the CD 125 on page 41, for example.)

But examples dominated by heavy amber swirls are also difficult to find and

equally desirable.

(page 29)

More on the cause of Swirls

Rust and flakes of metal are likely just one of the causes for the colorful

swirls we see in insulator glass.

In their book, "Insulators: A History and Guide to North American Pintype

Insulators, Volume 1", John and Carol McDougald wrote the following:

'Another commodity necessary for the production of insulators or any other

glass product is broken glass (cullet). In a letter received from Mr. N.R.

Woodward, author of "The Glass Insulator in America, 1988 Report", regarding

insulator colors, he shared the following:

'I think collectors often do not really comprehend the process of glass

manufacture on the commercial scale that was used to produce insulators. All

glass is composed of raw materials with sand as the primary ingredient, and cullet. All glass manufacture requires some cullet. Or (and this is important)

it can be all cullet. It cannot be all raw materials without cullet. Thus we

have our recycling efforts in many cities, where bottles are taken in and sorted

by color -- clear, brown and green.

'Back when the colored insulators were made, especially prior to World War I,

little attention was paid to color. The various manufacturers used different

methods. In one of their advertisements, Hemingray emphasized that glass should

be made with "not too much cullet". This was no doubt a slap at

Brookfield,

McLaughlin and others who largely used cullet. (See the ad on the opposite

page.)

'Natural glass color depends on the grade of sand used. The greater the iron

content the darker the aqua colors. If not a great deal of cullet is used, or if

it is clear glass, the color will remain fairly constant as long as the sand

source is not changed. As the cullet is increased, the colors will be affected;

and when a dark colored bottle was ground up and not completely mixed with other

glass, it would make a streak in the insulator. During the early years of the

(20th) century, we find amber streaks in some of the Hemingray insulators that

are generally of a uniform aqua color. Going back further, the Covington

production varied from some runs made with a high grade silica sand and of

uniform light tint, to others that seem to have been largely cullet and come in

every imaginable color.

'Brookfield used tremendous amounts of cullet at the Old Bridge plant and we

find not only dark green and brown streaks, but also pieces that were made with

a uniform mix of different colors and came out yellow-green, dark olive, etc.

'At times in every operation there were undoubtedly large amounts of a single

color of cullet brought in. A large number of clear bottles would lead to a

light purple and smoke glass so prized by collectors. At one time years ago when

I showed William McLaughlin one of his very dark green insulators, he said,

"Yes, we bought a truck load of green

ginger ale bottles from a defunct bottling works."

'Thus it can be seen that for the most part, the colors were unintentional,

and there is no limit to their variety. In more recent times where the buyers

became more particular, cullet was carefully controlled and decolorizing

formulae were used to produce essentially clear glass. But as collectors know,

there are occasional streaks of color even in late production.

'Other factors affecting color were, of course, the intentional blues and

ambers at Hemingray resulting from the addition of the proper minerals to the

mix; also the yellow and purples that resulted from attempts at decolorizer

formulae.'

(page 31)

CENTER PIECES

See page 34 for details about these insulators.

(page 32, 33)

Featured as our life sized centerfold pictures (pages 32-33) were:

CD 123 EC&M CO. SF. Aqua is the typical color for EC&M's. But they

are also famous for bright colors such as cobalt blue, olive amber, and deep

green. Minor amber swirling occurs frequently in CD 123' s. But when the

swirling dominates the insulator, the value soars. While not even as pronounced

as the EC&M shown on page 32, another heavily swirled EC&M brought

$5,775 at auction this spring. EC&M specialists may want to compare the

H-mold EC&M on page 32 with the B-mold style shown on page 44. Since

insulator presses ran with multiple molds at one time, some collectors wonder if

both of these insulators were produced simultaneously.

CD 257 "Mickey Mouse". All that solid glass in the ears of a

Hemingray Mickey Mouse add to the attractiveness of CD 257's. Dramatic swirling

only further enhances the appeal. This particular example has amethyst swirls in

the ears of an insulator otherwise described as being "ice aqua" in

color. Our efforts to show the amethyst swirls as best as possible has made the

insulator appear bluer than it really is.

CD 126 Blobtop. This is no Brookfield blobtop. Embossed "RD

149959", it is widely perceived that this 1880's era telegraph insulator

had its origins in England. It is possible, of course, that Brookfield made the

insulator for distribution in England. The company exported insulators on a

regular basis. This particular example, as we understand, was found in

California, on the east side of the Sierra Nevada mountains.

RD 149959 embossed blobtops are valued in the Price Guide from $1,000 in

green aqua to $1,750 for jade green milk. The special character of this specimen

makes it truly a Crown Jewel.

Insulators on the following two pages are described as follows:

Page 36:

Top Left: CD 102 Brookfield. Here's another example of where a common

Brookfield pony has become an uncommon Crown Jewel due to the infusion of amber

swirling.

Top Right: CD 101 Brookfield. This entire insulator is one big amber swirl,

with various degrees of intensity. Did Brookfield intend to make an amber

insulator? Or was there so much impurities in the batch of glass that the

insulator just came out looking amber? Is it a example of "too much

cullet"?

(page 34)

Page 36, continued:

Bottom: Here's a CD 127 Brookfield with a band of amber that weaves its way around and round the insulator.

Page 37:

Top: Canadian insulators are subject to amber swirling, too, as shown by this

"no name" CD 133. A dark band of amber hovers around the wire groove,

while lighter amber streaks brighten the dome. This is yet another insulator

made greener than it would otherwise be due to the impurities in the glass.

Bottom: Mexican insulators also become Crown Jewels due to swirling and its

affects. This is a CD 162.7 Derf showing swirling throughout, but particularly

strong in the dome.

Contributors to the article on swirled insulators:

Insulators: Swirled and streaked insulators shown in this month's magazine

are owned by collectors Bob Stahr, Bill Ostrander, Dwayne Anthony, James

"Pete" Dennis, Jeanne & Joe Bridges, Doug Williams, Mike Corn and

others.

Photographs: Pictures were taken by Bill Ostrander, Ray Klingensmith &

Howard Banks.

Color Printing: Color printing is made possible by a generous grant given to

Crown Jewels magazine by collector Tommy Bolack.

References:

Crown Jewels of the Wire, article "The Birth of an Insulator", by

Mark Lauckner, July 2000.

A History & Guide to North American Glass Pin type Insulators, by John

& Carol McDougald, 1990.

Insulators Price Guide, by John & Carol McDougald, 2003.

Hemingray advertisement reproduced from: The Hemingray Glass Company, A Most

Colorful History, by H.G. "BEA" Hyve, 1998

(page 35)

(page 36)

See Pages 34-35 for descriptions of these insulators.

(page 37)

|